Utilized Plastic Extrusion Lines – Pipe and Profile Purchasing Guide

Plastic line and profile lines can be utilized to make an assortment of items including pipes, tubing, straws, window outlines, divider trim, and home siding. The hardware to make plastic line and profile has not changed essentially lately and utilized gear offers an exceptional yield on venture. The average existence of new hardware from a respectable maker is 20+ years. Its life can be expanded if appropriately focused on and kept up. The main contemplations when purchasing new or utilized plastic line or profile line hardware are cost, usefulness and conveyance time.

Plastic Pipe and Profile Lines

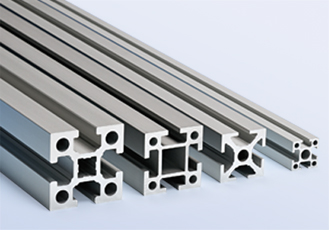

Lines and profiles are framed when plastic pellets are taken care of into an extruder, dissolved and passed on through a kick the bucket. The line or profile at that point goes into a water tank to be cooled and measured. In the event that the item needs to hold its shape during cooling, a aluminum extrusion applied to a water shower. Following this piece of the interaction, the line or profile is gotten through the water tank by a puller. At that point a shaper or winder is applied. With a shaper, the line or profile is sliced to a pre-assigned length. With a winder, the item is wound onto a spool or curl.

When buying a pre-owned line and profile line, consider the extruder make, type AC or DC and torque of the engine, barrel venting, kinds of controls, sort of feeder, state of the barrel and generally speaking appearance of the utilized extruder.

Another thought is the bite the dust. The kick the bucket needs to coordinate the rate and limit of the extruder as cast the right profile for the item. Hence, line and profile bites the dust are for the most part exceptionally fabricated and not bought on the pre-owned market.

When buying a water tank, think about the length, width, and tallness of the tank to guarantee the line or profile fits. It likewise needs adequate opportunity to cool. Additionally think about the development material: treated steel is favored in light of the fact that it does not rust however water tanks are likewise accessible in aluminum and carbon steel. On the off chance that the tank is under a vacuum, the number and sort of vacuum siphon is significant. The most widely recognized brands are Conair, Gatos, CDS and RDN.

Utilized pullers are accessible in two kinds: fitting or belt. Guarantee the width and contact length of the belt is suitable. Additionally think about engine pull and type AC or DC. Basic makers are Conair, Gatos, CDS, Farris, Boston Matthews, Metaphase, Goodman, ESI, and RDN.

There are two kinds of cutters: saw and flying blade. A saw is utilized on thicker lines and profiles and has a more slow activity. A flying blade shaper is utilized on more modest lines and profiles and works at higher paces. When buying a saw shaper, think about the width of the cutting edge and kind of controls for the unit. The limit ought to be estimated by the pace of the extruder and the remainder of the line. When buying a flying blade shaper, think about the limit, kinds of controls, brand and model. The framework can be air or servo electric driven with the servo electric drive offering more noteworthy precision. Makers incorporate Conair, RDN, CDS, and Farris Boston Matthews.